Language

Vacuum Concentrator

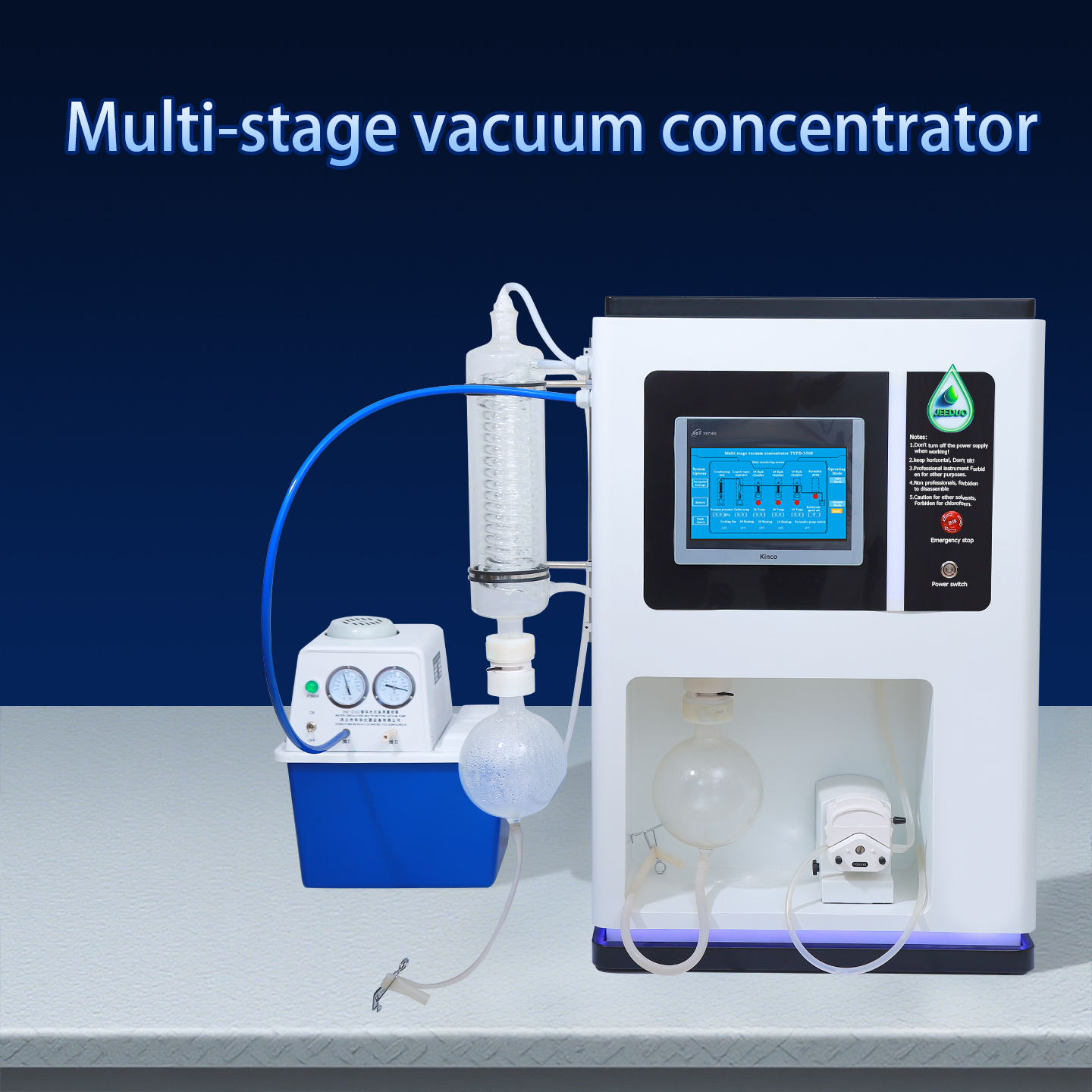

The multi-stage vacuum concentrator is an innovative liquid concentration instrument designed and manufactured based on the principle of "flash evaporation".

Based on lots of times test, this multi-stage vacuum concentrator can achieve precise quantitative liquid supply and efficient concentration.

Compared with traditional concentration instruments, this multi-stage vacuum concentrator has high concentration efficiency, short liquid heating time, protection of thermosensitive components from damage, low energy consumption.

This multi-stage vacuum concentratorasy is very easy on operation, and is suitable for rapid concentration of large amounts of liquids.

Tests show its concentration efficiency is over 30% higher than traditional methods, with superior performance in protecting heat-sensitive components, making it a replacement for traditional rotary evaporators.

This multi-stage vacuum concentrator can be used with a comined way to deal with big quantity liquids.

Based on lots of times test, this multi-stage vacuum concentrator can achieve precise quantitative liquid supply and efficient concentration.

Compared with traditional concentration instruments, this multi-stage vacuum concentrator has high concentration efficiency, short liquid heating time, protection of thermosensitive components from damage, low energy consumption.

This multi-stage vacuum concentratorasy is very easy on operation, and is suitable for rapid concentration of large amounts of liquids.

Tests show its concentration efficiency is over 30% higher than traditional methods, with superior performance in protecting heat-sensitive components, making it a replacement for traditional rotary evaporators.

This multi-stage vacuum concentrator can be used with a comined way to deal with big quantity liquids.

- Description

- Parameter

- Video

Suitable for the concentration of almost all solvents except for highly volatile, toxic, and highly corrosive substances such as ether and chloroform; After extensive experimental comparisons, the concentration efficiency is over 30% higher than traditional concentration methods, especially in protecting thermosensitive components, making it a replacement product for traditional "rotary evaporation".

| Traditional rotary evaporator VS Multistage vacuum concentrator | ||

| Traditional rotary evaporator | Multistage vacuum concentrator | |

| Principle | Rotating film concentration | Vacuum film concentration |

| Heating time | Long-term heating | 90 seconds heating |

| Efficiency (using water as the solvent | 0.8-1.0L/h | 3.5-4.0L/h |

| Comparison of processing concentration volume | The processing capacity is fixed | Automatic adjustment, without being limited by the amount of solvent, may be less more |

| The influence on heat-sensitive components | Destroy heat-sensitive components | Protect heat-sensitive components |

| Loss comparison | Serious solvent depletion | Effectively reduce the loss of solvents |

| Comparison of recoil phenomena of agents | It is easy to produce recoil | No recoil |

| Automated comparison | Low level of automation | High degree of automation, saving time and effort |

| Items | Parameters |

| Evaporation stage and power | 3 stages, 1200W × 3220V |

| Heating system | 3-stage series flash evaporation tube |

| Evaporation area | 0.7 ㎡ |

| Heating time of liquid | < 120S |

| Temperature regulation and fluctuation range | Room temperature~140 ℃, ± 5 ℃ |

| Heat transfer medium | High chain heat transfer oil (electric heating) |

| Liquid inlet method | peristaltic pump, continuous liquid supply (controllable speed) |

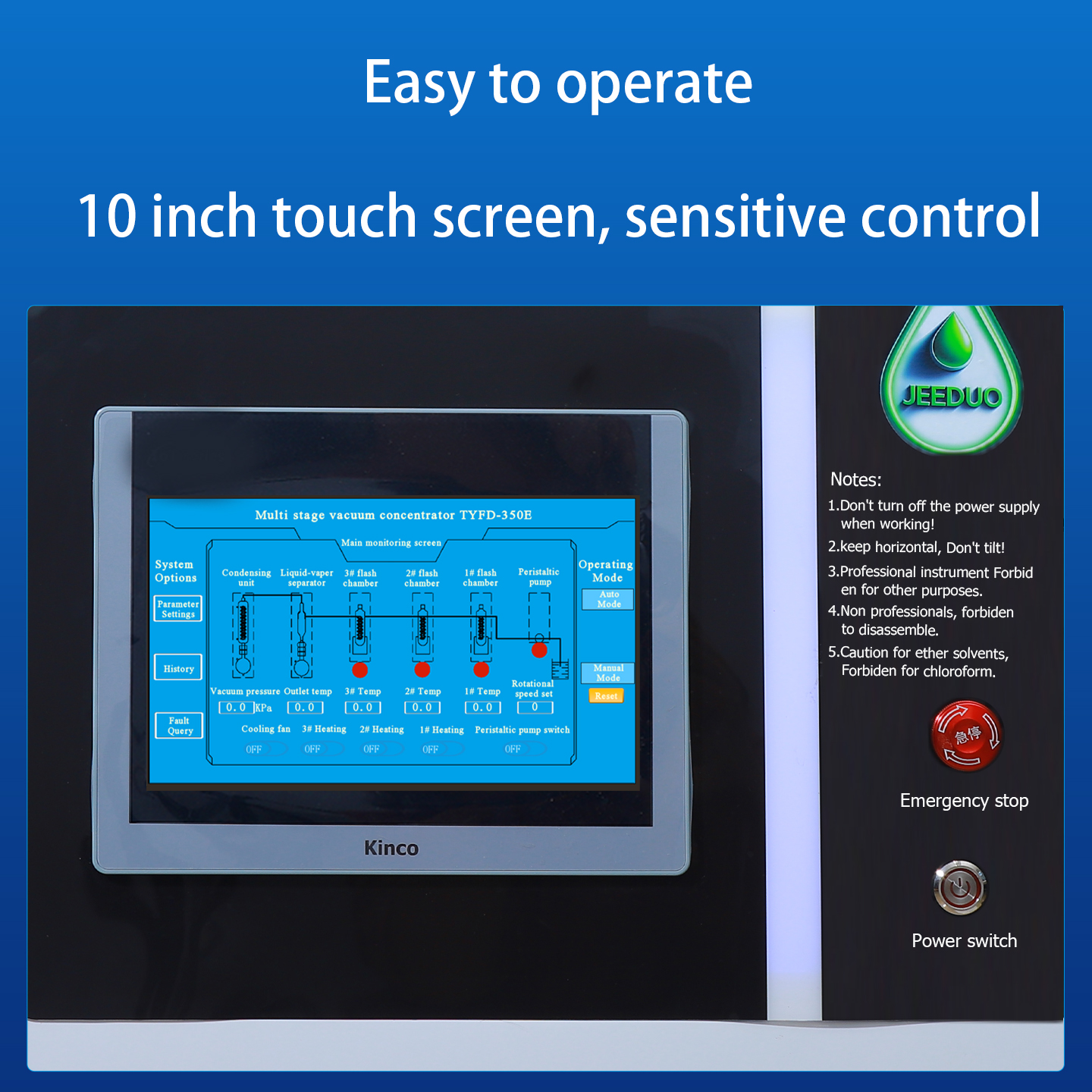

| Parameter setting and display | 10 inch touch screen |

| Liquid inlet speed | 0-400ml/min |

| Cooling System | Double layered cross flow high-density glass serpentine tube,circulating water or cooling water |

| Solvent distillation rate | 5000ml/h (water) |

| Main body dimensions | 650mm × 400mm × 1000mm |